Siding & Trim

Vinyl, aluminum, and steel siding were developed in the 1950s and 1960s and have been mass-produced for residential housing ever since. Chances are most of the homes in your neighborhood are covered in one of these three types of siding. Today, stucco, veneered stone, and mortarless brick can be installed to give your home a luxury designation without costing an arm & a leg.

Like your roofing material, your choice will impact a number of factors. Your Alpha Guru will work with you to determine what product is right for you based on factors including curb appeal, upkeep / maintenance, warranty, home resale value, & your budget.

Your Guru, following the Alpha Minded Process™ , will analyze your neighborhood & research what materials your city permits you to use.

Below are the different types of siding that your Alpha Guru will work with you to decide on:

Vinyl

- Vinyl siding is manufactured in hundreds of colors, so finding the “perfect” color for your home should be easy; the color is blended through the plastic, so scuffs or scratches will not leave noticeable blemishes

- Vinyl is molded in many surface textures and styles, including traditional or Dutch lap, scallops, shingles, fish scale, shakes, and various beaded designs; such diversity allows vinyl siding to complement historical homes and to provide design options for traditional and even eclectic homes

- Vinyl is impervious to insects, rot, and fungal or algal growth, and it stands up well to moderate impact

- Vinyl does not require routine cleaning or painting, and replacing sections of damaged vinyl is a farily simple process

- The main drawback to vinyl is that it expands and contracts with changes in temperature more than other materials, but it also shows end seams from one piece to the next—and these can be unsightly, making a house look plasticized

- For durability and appearance’s sake, vinyl is hard to beat

- Most varieties of top quality vinyl come with lifetime, transferable warranties (allowing the warranty to transfer from one homeowner to the next)

Metal Siding

- A percentage of the metal comes from recycled material and, depending on the finish coating, the siding may be recyclable when you replace it

- Metal siding has a factory-applied, high performance coating available in many colors, & is manufactured on lap styles as well as several embossed surface patterns

- Metal siding is galvanized for greater protection against corrosion

- The rigidity of steel and aluminum ensures a strength that vinyl cannot match — they will not buckle, sag, or distort

- Each panel can be custom fit to wall lengths to avoid the staggered seam appearance of viny

- Both steel and aluminum siding can be dented or scratched by a rogue baseball, rock, or falling tree branch

- Metal siding may be repainted without any preparation as long term UV exposure may degrade the painted finish on aluminum siding over time, leaving a chalky residue that occasionally needs washing

Stucco Siding

- Stucco is a mixture of Portland and masonry cements, sand, and water

- Variety of colorants can be added to the finish coat after it is installed in successive coats over a base of felt and metal lath & applied to either wood sheathed or masonry walls

- Stucco can be painted or texturized to offer a naturally blended appearance

- Lasts for decades with only an occasional restorative coat

- Stucco can crumble or crack as a house settles, but stucco generally proves to be a tough, low maintenance exterior finish

- Stucco may be used to coat entire exterior walls or for limited areas in conjunction with other siding materials

Stone Siding

- Mortared-in-place natural stone full of bricks are other attractive siding treatments to consider both are heavy and may required reinforced walls

- Price is driven up by quarrying and transportation, but difficult to match for beauty

- Common to combine rock with other forms of siding to help limit cost

Brick Siding

- Conventional bricks provide a rugged or refined elegance, depending on the style

- Durable, immune to insect damage, and fireproof

Simulated & Veneer Brick & Stone Siding

- Simulated materials bypass the costs of cutting and moving heavy materials

- Products are made of cement that’s cast into natural stone forms or brick shapes

- Color options vary & a wide array of simulated stone styles are available, including round, flat, textured, and smooth

- Veneered stone is fixed on place with mortar over a base of felt and vine mesh — it weighs a fraction of real stone, is more affordable, and the end result is very convincing

- Brick veneer is mortarless, stacking in interlocking courses on the surface of a sheathed and wrapped wall (there is no mortar because every fourth course is fastened with screws to furring strips)

Wood Siding

- Clapboard or shiplap siding is typically milled from cedar, cypress, redwood, or treated southern pine

- Wood siding offers excellent resistance to decay and insects

- Clapboard siding is usually manufactured with a tapered edge to create the proper overlap, and its installed horizontally

- Board-and-batten wood siding can be accomplished with ordinary lumber; its arranged vertically with a narrower wood strip that overlaps the seams between the boards

- Wood siding will generally cost more than vinyl or metal, and prolonged wetness will eventually lead to decay, and the wood will fade to gray unless you’re diligent about painting or staining every few years.

Shingle Siding

- Offering a warm, natural look. Wood has been used this way for centuries with excellent success

- Shingles and shakes are made from various species of cedar and cypress; white oak; and pressure-treated yellow southern pines

- The principal difference between wood shakes and shingles is how they are cut and processed: Shakes, more rustic than shingles, are sawn or hand split in varying thicknesses and lengths, but increase the chances for water infiltration if the wall and roof sheathing is not properly flashed and wrapped

- Shingles can be ordered with sanded, smooth surfaces or left with the natural woodgrain texture

- Wood shakes and shingles require regular maintenace & coating, however it can be walked on, is abrasion resistant, and easy to repair

Board & Batten Siding

- Board and batten appearance can be recreated with 4×8 sheets of exterior rated plywood that have a textured surface and a pattern of grooves to simulate the look of individual boards

- The edges of the sheets have overlapping tongues that hide the seams and help keep water out. Installation is easy for a competent homeowner with basic woodworking skills, and the material costs are about the same as vinyl siding

- Must be carefully installed and properly flashed so the back surfaces

- Needs protective topcoat of paint or stain to prevent deterioration from moisture or sunlight

- As the panels age, its common for the laminated layers to begin to separate. But, when the sheets eventually wear out, they’re easy to replace.

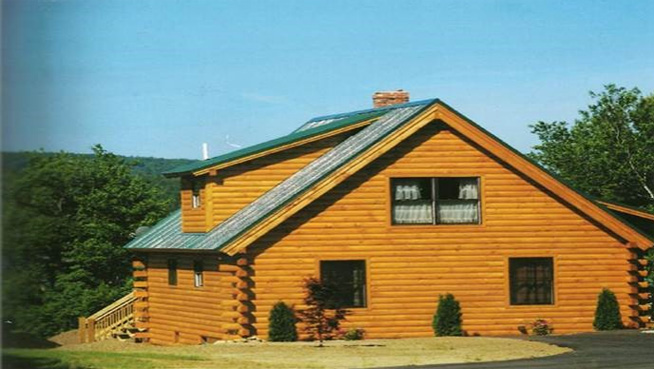

Log Cabin Siding

- Log cabin sliding is yet another wood siding alternative

- White pine or cedar logs are stripped of back, and then sawed into thin lengths of siding with the curvature of the log’s surface left intact

- It takes close inspection to realize that walls are not made of white logs

- Needs a top coat like other wood siding options to extend its serviceable life as it is prone to moisture & pests

- Its priced comparably to wood shakes or shingles.